RED DEER’S CHOICE FOR CONCRETE DRIVEWAY REPAIR

As sturdy and durable as it might seem, concrete does break down over time. Ravaged by the weather and damaged by erosion, soil compaction, and drainage issues, concrete driveways, walkways, patios, basements and garage floors can become cracked and dangerous. When a slab starts to sink, it can create an assortment of issues. Sinking is often the result of poor initial installation or inadequate soil compaction. Polylift has a solution for every problem, whatever the cause. Our team of experts have been making it right for nearly a decade now. We’re the contractor of choice for residential, commercial and industrial concrete concerns in Red Deer and Central Alberta and we deliver superior, affordable and long-lasting results every time!

We’ve got the tools and the know-how to get the job done right! Once we assess the situation, we drill holes into the affected slab and then inject a unique polyurethane mixture through these holes, returning the slab to a correct level. As mentioned, this process costs significantly less than replacing the slab and happens in a fraction of the time. Polylifting can be performed anytime during the Spring, Summer or Fall and does not affect existing landscaping. It’s the ideal way to eliminate a variety of issues including tripping hazards, poor drainage, liability concerns, unappealing aesthetics and the big one, property devaluation!

Polyurethane foam is eco-friendly, will never erode nor wash away, making it a perfect compound for stabilizing concrete in a fast, efficient, and cost-effective manner. Sunken, cracked or unsightly concrete can dramatically affect the appearance and overall value of your property. At Polylift, we work hard to deliver results that meet or exceed expectations.

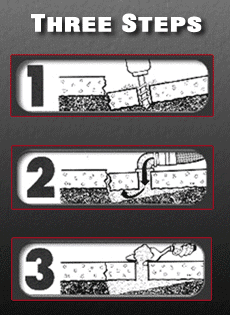

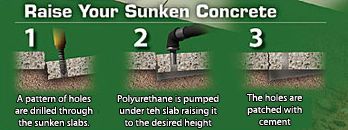

THE POLYJACKING PROCESS:

The polyjacking process is relatively simple and consists of three stages:

First, a series of hold are strategically drilled in the sunken concrete slab.

Second, polyurethane foam is hydraulically pumped beneath the slab, elevating it to the desired height. The amount of rise is carefully monitored by the Polylift team.

Third, once the concrete has been raised to the appropriate level, the injection holes are filled using a fast-setting sand/cement patching compound.

MATERIALS USED:

Our levelling foam is a high-density polyurethane formulation with a minimum compressive strength of 40-pounds per square inch (PSI). It will reach 90 per cent of full compressive strength within approximately 15-minutes from the time of injection.

- Density, Lb/Cu Ft Compressive Strength

- (ASTM D1622) (ASTM D1621)

- 3.0 (48 kg/m3) 40 psi (275 kPa)

- 3.5 (56 kg/m3) 50 psi (344 kPa)

- 4.0 (64 kg/m3) 60 psi (413 kPa)

- 6.0 (96 kg/m3) 110 psi (758 kPa)